Bunding solutions

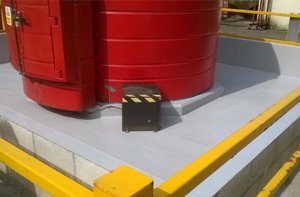

We help organisations to ensure their secondary containment, specifically their bunds are compliant by designing, constructing, inspecting, and maintaining them to current standards and good practice.

Secondary containment is the method of containing leaks or spills if the primary containment measures fail. Secondary containment is an essential hazard prevention strategy that is specifically designed to prevent the substances from escaping the storage facility or immediate workplace.

Bunds are a key component of any secondary containment strategy. Placed around the perimeter of the containment area, bunding is designed to stop spills from spreading further.

How we can help

Design and construction

Inspection and maintenance

Benefits

- In-house experts in bund audits, inspections, cleaning, and lining.

- We have decades of experience specifying bunds to individual requirements.

- Compliant with CIRIA C736, COMAH and HSE guidelines.

Added value

Inspection and maintenance

Design and construction

Lining and protection

Two of the key pieces of legislation that you could breach if you don’t properly maintain your secondary containment are:

The Water Resources Act 1991 states that ‘It is an offence to cause or knowingly permit any poisonous, noxious or polluting material, or any solid waste to enter any controlled water.’

Environmental Permitting Regulations 2016 state that ‘It is an offence to cause or knowingly permit a water discharge activity or a groundwater activity without an environmental permit.’

A pollution incident because of a poorly maintained asset or inadequate containment is a strict liability offence and failure to adhere to standards and good practice guidance is a key factor in considering enforcement action.

The onus is on operators to demonstrate compliance with regulation to reduce the risk of a pollution incident. A robust asset maintenance programme is essential for providing the information needed for service log scrutiny in the event of an incident or during routine environmental inspections.

The implications of failing to adequately protect the environment range from environmental, legal, financial, and reputational.

Relevant standards and good practice

- CIRIA C736 Containment systems for the prevention of pollution

- PPG 2 – Above Ground Oil Storage Tanks

- GPP 2 – Above Ground Oil Storage Tanks

- GPP 21 – Pollution Incident Response Planning

- HSG 176 - The Storage of flammable liquids in tanks

- HSG 51 - Storage of flammable liquids in containers

- HSE/PSLG - Safety and environmental standards for fuel storage sites

- Hazards 27 - Inspection of Secondary and Tertiary Containment Systems

- There are a number of specialist containment guidance notes for high hazard inventories such as bromine and chlorine

CIRIA C736

Regulator issued CAR (Compliance Assessment Report) papers state that operators must provide evidence that their asset/facility meets CIRIA C736.

A baseline asset survey of each secondary containment facility should be completed and reviewed by a competent person to demonstrate it is reducing risk sufficiently to satisfy the law.

A gap analysis should be completed to highlight any shortcomings with the existing secondary containment facility compared to the class required by the use. Where practicable, these shortcomings should be addressed. However, if it is not considered practical then alternative measures should put in place such as tertiary containment to reduce the risk sufficiently to satisfy the law.

Duty holders should prepare an appropriate inspection and maintenance regime for their facilities. Where one does not exist, each containment facility should be classified. The classification should be reviewed at least once every five years, or where:

- there are any modifications made to the primary or secondary containment.

- the volume of material in the primary containment is increased.

- the nature of the material in the primary containment is changed.

Keep your business compliant and protect the environment while reducing the risk of operational downtime

Find out how Adler and Allan reduce your risk and support you on your journey to Net-Zero through the management and maintenance of assets.

Contact our experts