Protective coating and lining

Ready to discuss your project?

Please leave your details and a member of our team will reach out to discuss your requirements in more detail and arrange next steps.

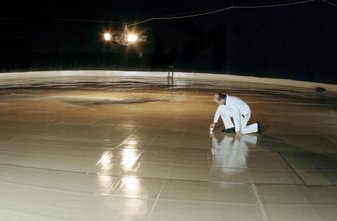

We specialise in revitalising and prolonging the life of your valuable assets through the expert application of protective coatings and linings.

We offer practical and cost-effective solutions that shield your assets from the detrimental effects of abrasive or corrosive environments.

Our range of industrial linings and chemical-resistant coatings can be tailored to meet your operational requirements and specific chemical hazards, providing proven, robust measures against asset degradation.

We take pride in providing a diverse range of solutions that can be applied across a wide range of applications, including:

- Repair, maintenance, and lifespan extension: Products and applications to refurbish and extend the operational life of your assets.

- Water ingress prevention: Employing cutting-edge techniques to safeguard against water infiltration.

- Compliance assurance through proper containment: Ensuring regulatory compliance by implementing effective containment measures.

How we can help

AdlerCoat™ polyurea and epoxy coating

Hydrophobic coatings

Double-skin underground tank lining

Cured-in-place pipe (CIPP) lining

You might also be interested in...

Environmental compliance today, creating a sustainable tomorrow

Helping you reduce risk to the environment and your operation by managing assets compliantly while achieving commercial, ESG, and net-zero goals.

Contact our experts