Environmental management for the aviation sector

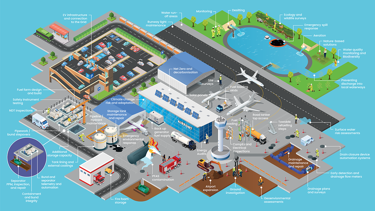

We work with airport operations, ground support and infrastructure owners to maintain your ageing assets, install new fuel infrastructure, and manage your environment so that you can ensure compliance with environmental regulations, reduce downtime, and achieve your sustainability ambitions.

The next decade will see momentous change within the civil aviation sector as passengers return, alternative fuels gain ground, and the world moves towards decarbonisation and Net-Zero.

With our heritage in defence aviation, we’re bringing military precision and standards to the civil sector. Our expertise helps you uphold quality standards in a heavily regulated environment – and avoid financial penalties and consumer dissatisfaction arising from delays or increased costs.

Additionally, we’re helping organisations refine their infrastructures to adapt to the substantial requirements of new fuel legislation and fuel types.

Tackling key challenges in the aviation sector

Given the complexities of Regulation 61 and the potential risks associated with non-compliance, airports require reliable support. We offer a comprehensive range of services to help airports navigate this regulatory landscape effectively.

Site surveys

Our expert team conducts thorough site surveys to identify potential hazards, assess infrastructure, and evaluate compliance with environmental regulations. This baseline information informs subsequent monitoring and corrective actions.

Screening procedures

We conduct detailed assessments of your airport's operations to identify potential sources of pollution and evaluate associated environmental risks. This information is used to develop strategies for mitigating these impacts and ensuring ongoing compliance.

Monitoring programmes

Regular monitoring is essential for maintaining compliance. Our programmes include surface water risk assessments to evaluate pollution potential and identify areas for improvement.

Compliance audits

Our compliance audits verify adherence to environmental regulations, identifying non-compliance areas and providing targeted recommendations for corrective actions.

Environmental management systems (EMS)

We assist airports in developing and implementing environmental management systems that meet international standards like ISO 14001. This EMS provides a structured approach to managing environmental risks and improving performance.

Staff training and awareness

Our tailored training programmes ensure staff understand environmental regulations, potential impacts, mitigation strategies, and emergency response.

Regulation 61 is a critical aspect of ensuring responsible airport operations. By understanding its requirements and seeking the right support, airports can effectively navigate the compliance landscape and contribute to a more sustainable future. We are committed to helping airports achieve their environmental goals while maintaining their important operations.

Airport expansion is a complex endeavour that requires careful planning and execution. As global travel continues to grow, airports face the challenge of balancing increased capacity with environmental responsibility. By incorporating sustainable practices and leveraging expert guidance, airports can ensure that their expansion projects are both beneficial and environmentally friendly.

One crucial aspect of airport expansion is the assessment of land conditions. Contaminated land can pose significant environmental risks and may require remediation before development can proceed. Our experts conduct thorough contaminated land assessments to identify potential issues and develop tailored remediation plans. This involves site investigations, risk assessments, and the creation of effective remediation strategies. Involving an Environmental expert like Adler and Allan at the outset can help de-risk land transactions if further purchase of land is required for expansion.

Preserving biodiversity is another key consideration in sustainable airport expansion. Our ecologists conduct comprehensive surveys to assess the ecological value of proposed expansion sites and identify sensitive habitats or species. These surveys include preliminary ecological appraisals and ecological impact assessments. By understanding the environmental implications of their projects, airports can implement measures to minimise negative impacts and even enhance biodiversity.

The construction of new infrastructure, such as runways, terminals, and fuel storage facilities, is often a necessary component of airport expansion. We provide expert services to ensure that this infrastructure is designed, installed, and maintained in a sustainable manner. This includes the design and installation of fuel infrastructure, grid connection for EV charging and high voltage connections, and the incorporation of sustainable design principles.

Obtaining necessary environmental permits and ensuring ongoing compliance with regulations is essential for successful airport expansion. We offer guidance and support throughout the permitting process and help airports develop effective environmental management systems. This involves assisting with permit applications, monitoring compliance, and implementing sustainable practices.

By incorporating sustainable practices and seeking expert guidance, airports can ensure that their expansion projects are both successful and responsible.

Effective water and drainage management is crucial for the safe and efficient operation of airports. Compliant drainage systems prevent flooding, erosion, and contamination, protecting both the environment and airport infrastructure. From runways to terminals, proper drainage ensures smooth operations, even in heavy rainfall. Regular inspections, maintenance, and adherence to strict regulations are essential to maintaining a safe and resilient environment for your airport.

Water quality monitoring is a vital aspect of airport drainage management. We help airports improve their environmental impact by providing evidence of compliance with discharge permits and assessing the impact of uncontrolled discharges. De-icer, a commonly used substance at airports during winter months, can pose a significant risk to water quality. Our monitoring programs can help airports track the quality of their discharges and the receiving watercourse, ensuring that environmental standards are met.

A well-designed drainage plan is essential for preventing flooding and ensuring the smooth operation of an airport. Our experts develop comprehensive drainage plans that take into account the specific needs and characteristics of each airport. This involves site assessments, design, and construction support.

Correctly designed water runoff areas are essential for airports. These areas prevent flooding, erosion, and contamination, safeguarding both the environment and airport operations. By effectively managing rainwater, we can protect critical infrastructure and minimise any disruption to airport operational activities. We provide services for the design and maintenance of runoff areas, as well as implementing measures to prevent erosion.

Effective drainage management is a vital component of sustainable airport operations. By investing in water quality monitoring, drainage planning, and water runoff management, airports can ensure the safety, efficiency, and environmental sustainability of their operations.

The aviation industry is undergoing a transformative shift as it seeks to reduce its environmental impact. One of the most promising avenues for achieving this goal is the adoption of new aviation fuels. These cleaner alternatives, such as Sustainable Aviation Fuel (SAF), offer a significant reduction in carbon emissions compared to traditional jet fuel. UK airports are at the forefront of this transition, investing in infrastructure and adopting new technologies to support the growing use of these environmentally friendly fuels.

The introduction of new aviation fuels, such as SAF, represents a major step towards a more sustainable aviation industry. These fuels are derived from a variety of renewable sources, including waste cooking oil, agricultural residues, and forestry by-products. By replacing traditional jet fuel with SAF, airports can significantly reduce their carbon emissions and contribute to climate change mitigation.

To support the growing use of new aviation fuels, airports need to invest in new fuel infrastructure. This includes storage facilities, refuelling stations, and pipelines for alternative fuels like SAF and potentially hydrogen. By developing this infrastructure, airports can ensure that they have the capacity to handle these new fuels and meet the needs of airlines and aircraft manufacturers.

Fuel loading operations are a critical component of airport operations. By improving these processes, airports can increase efficiency, safety, and sustainability. New fuel loading skids, designed and built by our group company Flotech, offer advanced technology and improved safety features, enhancing fuel transfer processes and reducing the risk of spills. Investing in this essential infrastructure can help airports streamline operations and contribute to a more sustainable aviation industry.

Many airports are setting ambitious targets to achieve net zero carbon emissions. To achieve this goal, airports must take a comprehensive approach that includes reducing emissions from aircraft operations, ground vehicles, and airport facilities. By investing in new aviation fuels and implementing energy-efficient practices, airports can make significant progress towards their sustainability goals.

We play a crucial role in supporting airports on their journey towards sustainability. Our services include energy audits, ESG consulting, infrastructure development, and compliance support. The transition to new aviation fuels represents a significant opportunity for the aviation industry to reduce its environmental impact.

Related services

Assets and infrastructure

Drains and sewers

Fuel infrastructure

Water quality monitoring

Hazardous and specialist electrical

Logistics, blending and storage

Sustainability and Net-Zero

Firewater containment planning

Added value

- We are security cleared to work on civil and military airport sites

- We know how important your customer data is and we manage it professionally and carefully

- 24/7 365 response nationwide

- Experts in environmental legislation so we can keep you compliant and reduce downtime

Key contacts

Matt Tolan

Contact a sector specialist

If you'd like to get in touch with a sector specialist, please leave your details and a member of the team will be in touch.

You might be interested in...

Environmental compliance today, creating a sustainable tomorrow

Helping you reduce risk to the environment and your operation by managing assets compliantly while achieving commercial, ESG, and net-zero goals.

Contact our experts